© 2024 شركة Zhangjiagang Radar Beverage Machinery Co.,LTD. جميع الحقوق محفوظة. سياسة الخصوصية

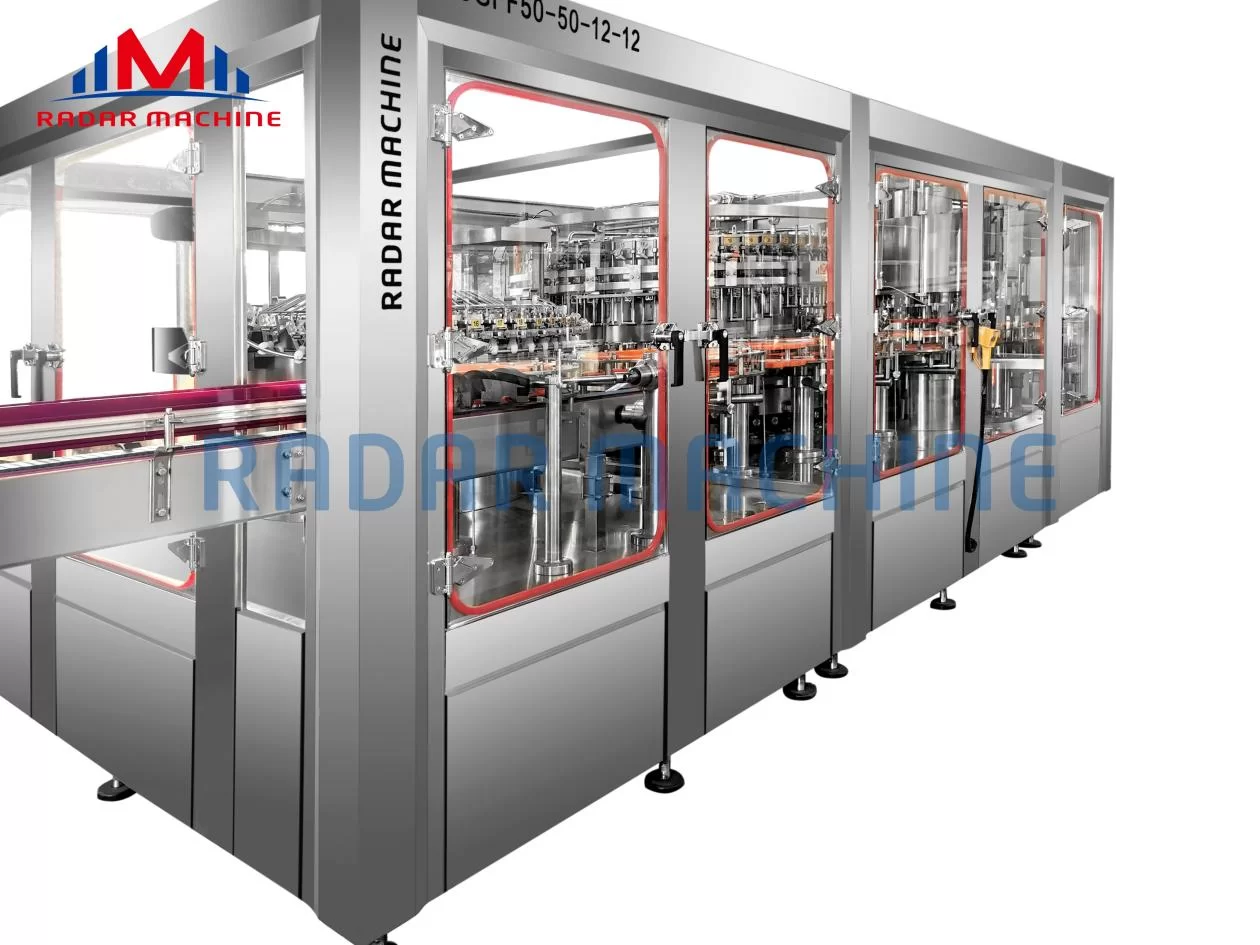

The beer filling machine is used to fill beer into bottles, cans, or other containers. It first cleans and disinfects the containers to ensure hygiene. Then, it precisely fills the beer and seals the containers. The machine also includes inspection features to ensure the correct fill level and seal quality. Finally, the filled and sealed containers are packaged and prepared for shipment.

We have 10 years of experience in production design for the customer solve the problem of PET water production line, we can help you with the most advanced technology, with the lowest cost to achieve production goal, our company regards quality as enterprise life, and this concept through to production of each link, to provide customers with excellent equipment is the goal of our efforts.

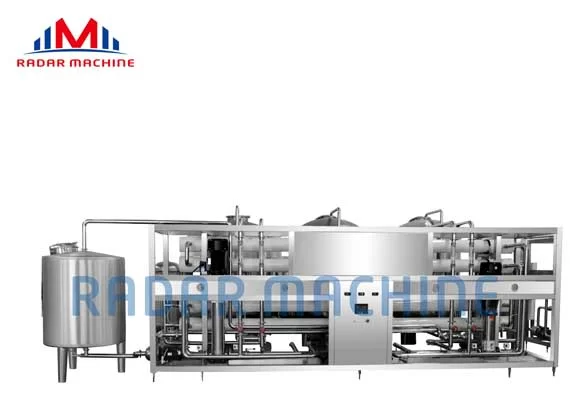

View Details →Used for pure water, mineral water and other bottled water, water for food and beverage production.It is mainly composed of the following equipment water-treatment system (water tank, multi-medium filter, active carbon filter, ionexchanger, millipore filter), membrane separation system (ultra filter, nanometer filter, RO system), electrodialysis device, sterilization system (UV device, ozone device), product water tank and so on.

View Details →

Adopting advanced fermentation technology, the temperature and humidity in the fermentation process are precisely controlled to ensure that yeast efficiently converts the sugar in the wort into alcohol and carbon dioxide, thereby brewing beer with pure flavor and stable quality, providing core support for the production of high-quality beer

View Details →It can efficiently clean the inside of the equipment through circulating cleaning fluid without disassembling the equipment, ensuring the hygiene and safety of the production equipment.

View Details →

As a key equipment for beer production, Radar beer filling machine adopts advanced automation technology to ensure that every link from bottle washing, beer filling to bottle mouth sealing is efficient, accurate and hygienic. Its working principle includes that the clean bottles coming out of the bottle washing machine are sent to the bottle feeding screw of the filling machine by the bottle conveyor belt, and the beer is injected into the bottle through the precise filling valve, and the control system is used to achieve precise control of the filling volume and speed. In addition, the equipment also has two filling methods, high pressure and normal pressure, which are suitable for different types of beer to ensure the quality and taste of each bottle of beer.

View Details →Tailor-made for the beverage industry, it can achieve precise sterilization and cooling of bottled beverages in an efficient and energy-saving manner to ensure product quality and safety.

View Details →

Radar blow dryer: specially designed for the beverage industry, it can effectively dry the bottle, ensure clear coding and dry packaging, and improve production efficiency and product quality.

View Details →The Radar inkjet printer is designed specifically for the beverage industry. It has efficient, accurate and flexible labeling capabilities and can meet various coding needs on beverage production lines. The following are the main functions and advantages of the Radar inkjet printer

View Details →

Tailor-made for the beverage industry, with efficient and accurate labeling to improve production efficiency and product quality.

View Details →Provides efficient and intelligent packaging solutions for the beverage industry. It has functions such as automatic bagging, weighing, bag clamping, filling, conveying, folding and sewing. It adopts gravity feeding and ensures the feeding speed and accuracy through instrument control. Its intelligent operating system can monitor and adjust various parameters in the packaging process in real time to ensure the stability and consistency of packaging quality.

View Details →

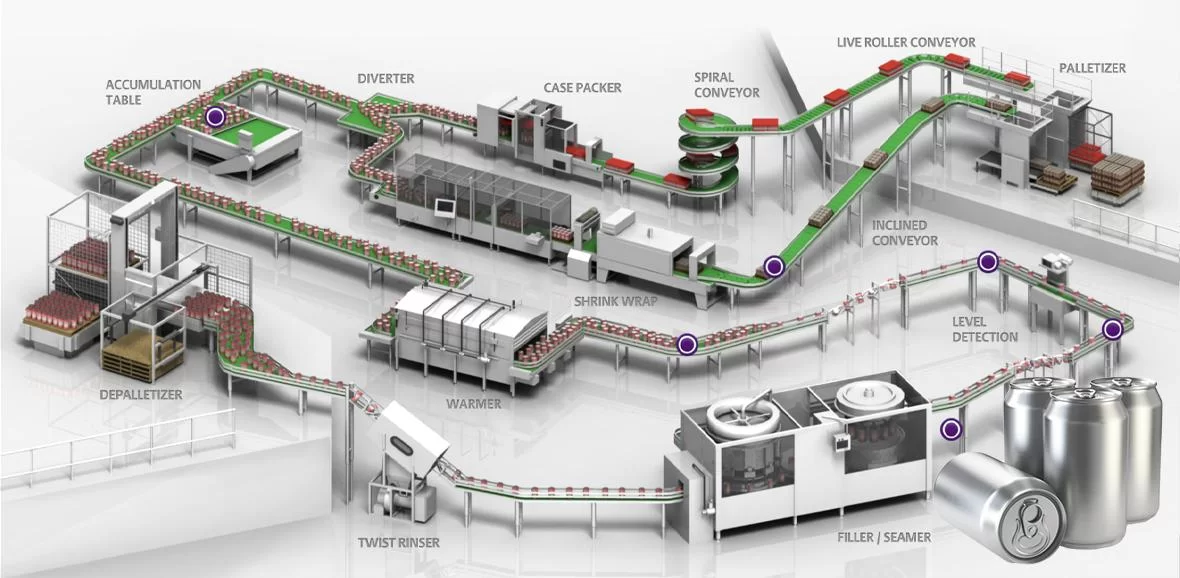

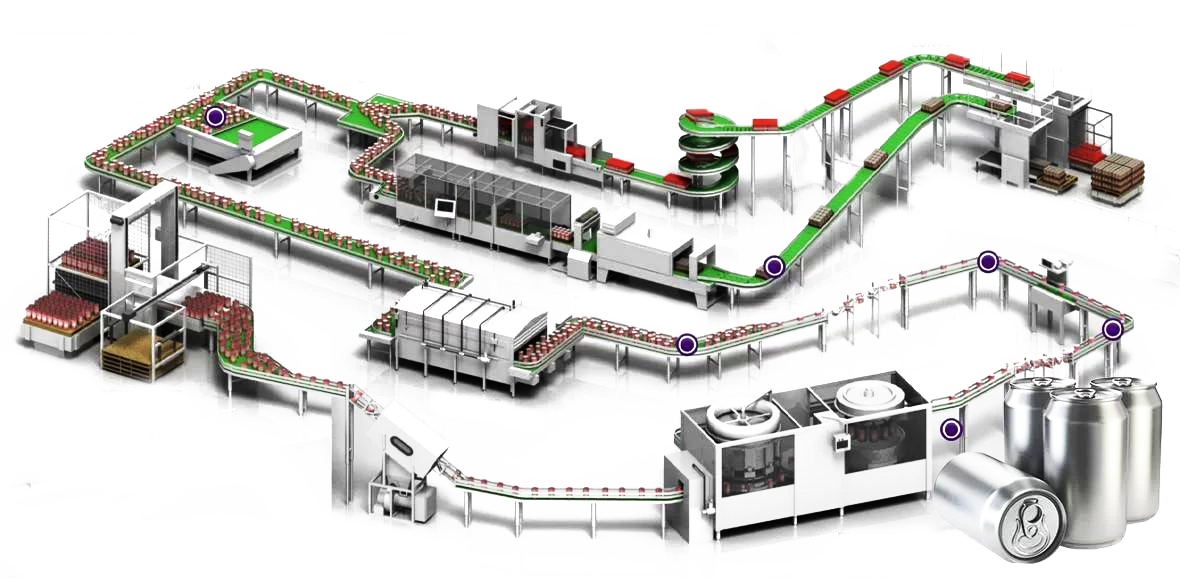

Radar palletizer is an indispensable automated equipment in beverage production lines. It can efficiently and accurately stack packaged beverage products neatly on pallets, improve production efficiency, reduce labor costs, and ensure the convenience of storage and transportation.

View Details →