© 2024 Zhangjiagang Radar Beverage Machinery Co, LTD. Semua hak dilindungi undang-undang. Kebijakan Privasi

As Customer Service, we share the same goal:

the optimum, reliable operation of your equipment throughout its entire service life. Our globally active customer service team

provides you with support in ensuring and improving machine performance, if required. Close cooperation,

efficient communication and high flexibility are key elements of service philosophy.

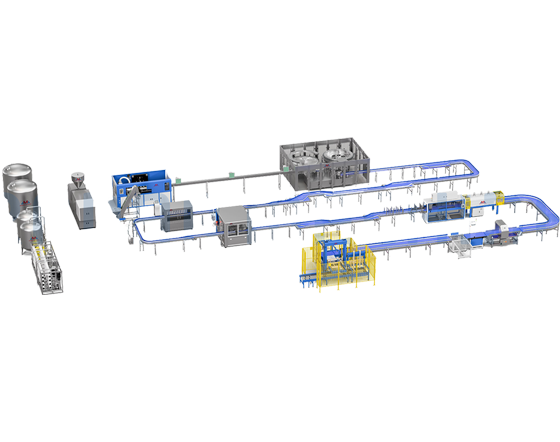

We have 10 years of experience in production design for the customer solve the problem of PET water production line, we can help you with the most advanced technology, with the lowest cost to achieve production goal, our company regards quality as enterprise life, and this concept through to production of each link, to provide customers with excellent equipment is the goal of our efforts.

View Details →Purpose: This blow molding machine is designed for carbonated beverage filling production lines. It is mainly used to produce high-quality carbonated beverage bottles. It can also be used for the production of various beverage packaging bottles such as mineral water bottles and juice bottles to meet the large-scale production needs of different beverage production companies.

View Details →

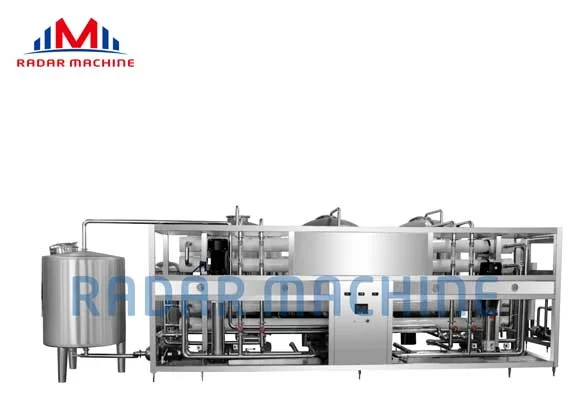

Used for pure water, mineral water and other bottled water, water for food and beverage production.It is mainly composed of the following equipment water-treatment system (water tank, multi-medium filter, active carbon filter, ionexchanger, millipore filter), membrane separation system (ultra filter, nanometer filter, RO system), electrodialysis device, sterilization system (UV device, ozone device), product water tank and so on.

View Details →As an advanced beverage production solution, the Radar brand blending system has a high degree of automation and precise metering capabilities, and is suitable for a variety of beverages, including fruit juice drinks, milk drinks and carbonated drinks. The system uses advanced mixing technology and automatic control systems to ensure uniform mixing of materials and stable operation. It can be customized according to customer needs and equipped with heat preservation and heating devices to meet the ingredients and temporary storage requirements of different products.

View Details →

Radar blow dryer: specially designed for the beverage industry, it can effectively dry the bottle, ensure clear coding and dry packaging, and improve production efficiency and product quality.

View Details →The Radar inkjet printer is designed specifically for the beverage industry. It has efficient, accurate and flexible labeling capabilities and can meet various coding needs on beverage production lines. The following are the main functions and advantages of the Radar inkjet printer

View Details →

Tailor-made for the beverage industry, with efficient and accurate labeling to improve production efficiency and product quality.

View Details →Provides efficient and intelligent packaging solutions for the beverage industry. It has functions such as automatic bagging, weighing, bag clamping, filling, conveying, folding and sewing. It adopts gravity feeding and ensures the feeding speed and accuracy through instrument control. Its intelligent operating system can monitor and adjust various parameters in the packaging process in real time to ensure the stability and consistency of packaging quality.

View Details →

The Radar weighing and testing machine is an indispensable quality control equipment on the beverage production line. Through high-precision weighing sensors and advanced data processing systems, it monitors and controls product weight in real time to ensure that each beverage product meets strict weight standards.

View Details →Radar palletizer is an indispensable automated equipment in beverage production lines. It can efficiently and accurately stack packaged beverage products neatly on pallets, improve production efficiency, reduce labor costs, and ensure the convenience of storage and transportation.

View Details →