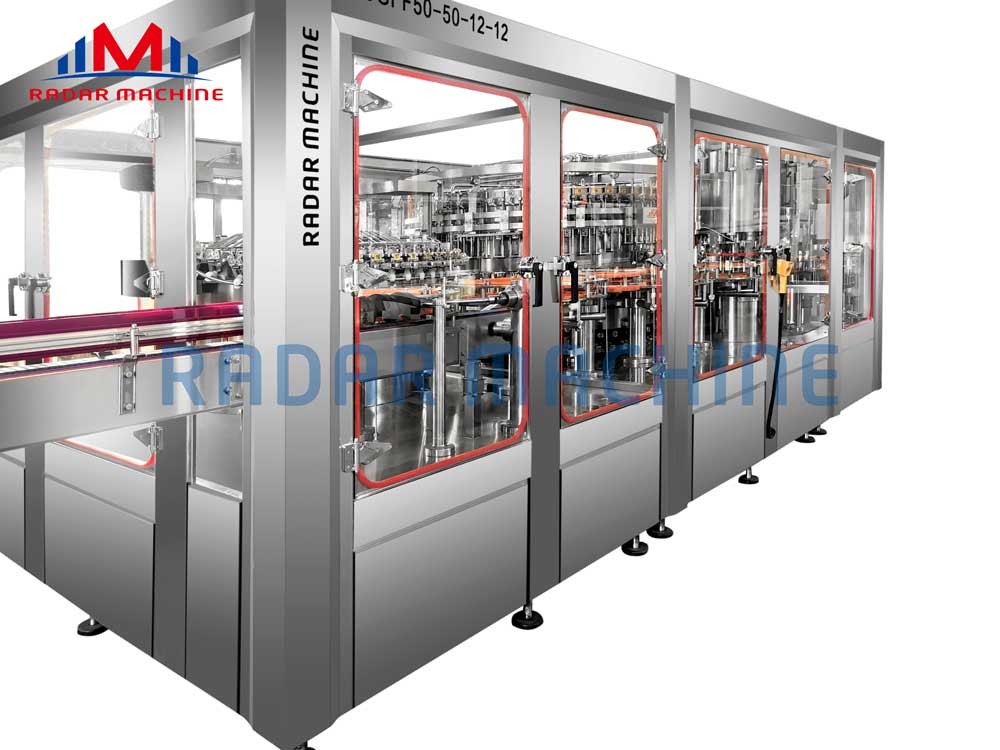

Carbonated Soft Drinks Mixing System

- Suitable for food processing in various industries.

- Can be used in large restaurants for cooking tasks.

- Improves quality, reduces cooking time, and enhances working conditions.

Detailed Images

Video

Machine Parameters

Blend tank/ Mix tank

Stir, mix, blend, and homogenize the materials. The design structure and configuration can be standardized according to the requirements of the production process. Stirred tank during agitation can be achieved feed control, the feed control, stirring and other manual controls automatic control

CO2 Mixer

Beverage Mixing Machine is used to mix CO2 with beverage, it is suitable for all types of carbonated drink processing. It is the necessary and important beverage mixing machine for carbonated drink processingThe beverage carbonator is used for mixing all kinds of carbonated drink with high gas ration.

It mixes the water, sugar, gas together for high quality gas drink, adopts the newest technology.

Chiller

Drinking Water Chiller, Carbonated Drink Mixer Chiller, Wort Chiller for Beverage Processing.

The chillers are special designed for beverage processing, maintain temperature at 4 deg. c. The heat exchange unit is made up of stainless steel 304 food grade Hygienic step tubes.

| Model | QHS-2500 | QHS-5000 | QHS-7000 | QHS-10000 | QHS-15000 |

|---|---|---|---|---|---|

| Production Capacity(B/H) | 3000 | 5000 | 7000 | 10000 | 15000 |

| Water sugar ratio | 3:1-6:1 | ||||

| CO2 content | 3:08 | ||||

| Mixing temperature | <4℃ | ||||

| Power consumption(Kw) | 4.45 | 5.9 | 7.2 | 10.2 | 13.6 |

| Overall Dimension(L*W*H)(mm) | 2900*1500*2600 | 3000*2000*3000 | 3500*2300*3200 | 3500*2300*3200 | 3800*3600*3200 |

| Weight(KG) | 2500 | 3000 | 3500 | 4000 | 4500 |

Faq

a. What kind beverage you want to produce? Water , juice , carbonated drinks , beer and etc.?

b. contain type, shape and volume? Round, square , 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d. Factory floor plan , voltage and power supply?

e. Your investment and budget?

We are a manufacturer we supply the factory price with good quality, welcome to visit !We can pick you up from at the Zhangjiagang station in our city or in Shanghai airports. Contact our foreign sale team you can get video of our reference running machine.

We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories and check the machines running. You are always welcome to visit our factory in Chine to check the machine running in our factory.

Turnkey projects are available because we can help to start your business in beverage market from PET preform and can making machine, PET bottle blowing machine, water treatment plant , juice or carbonated drink mixing plant , filling and packing machines.

If you have confirmed your size , we help you with the plant layout design accordingly .We can also help with the bottle design, label design and choose the suitable labeling and package type according to your local market. We can help you install the machines, train your staff to operate, maintain the machines and even help you hire experienced Chinese engineers to work in your factory as a production manager .

We have been certificated by the famous certification authority such as ISO and CE .

We offer you high quality machines with 1 year guarantee and provide vulnerable parts free of charge. Every batch of equipments will be debugged before shipment by sending testing video for confirmation. Or you can visit our factory for inspections on site and then ship it after it is qualified. We also supply life-long technical support.

A. If you have clear demand, please inform us, we will make detailed good quote for you soon.

B. If you are new in this filed and don't have clear objectives, you can share us your ideas, investment budget or workshop size, we can make proposal recommendation for you.

When you finish the Preparation conditions(water resource,electricity,air supply,production materials)contact with our sales people we will dispatch engineer to install the machine for you ,and train your employees to use the machine well. Normally when your preparation is done,you can contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 7 days.

We will send one year enough easy broken spare parts together with the machines,shipping together.During the warranty time,we will supply the spare parts with our cost including the delivery fees.

We accept 30% deposit 70%TT before shipment by TT/LC/Western union.

Standard export packing, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety.