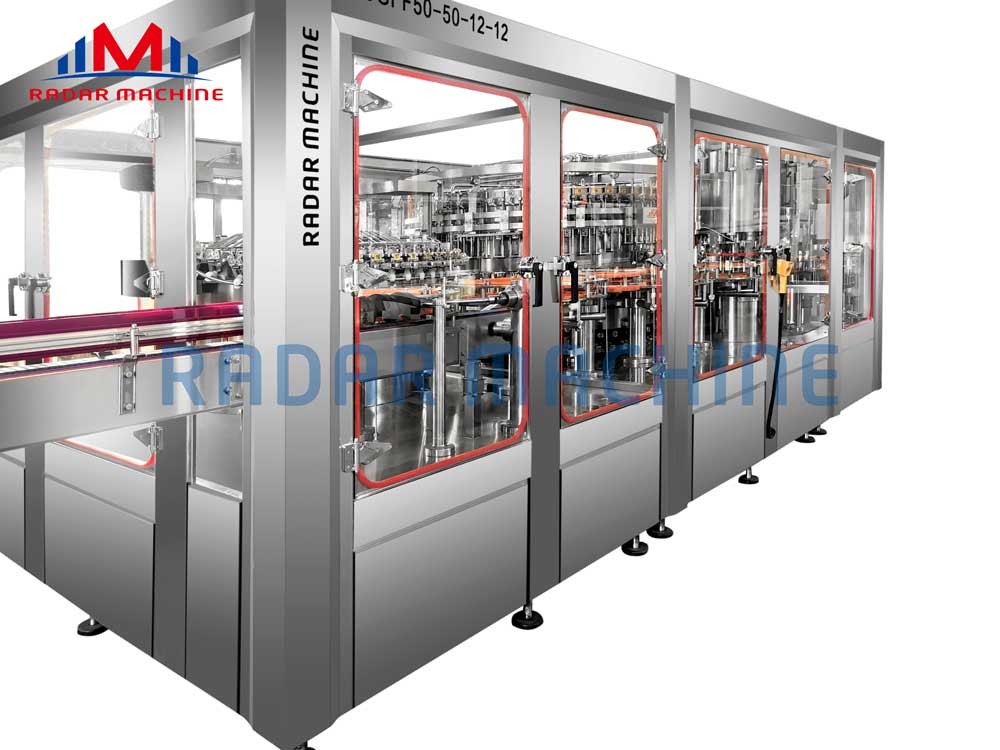

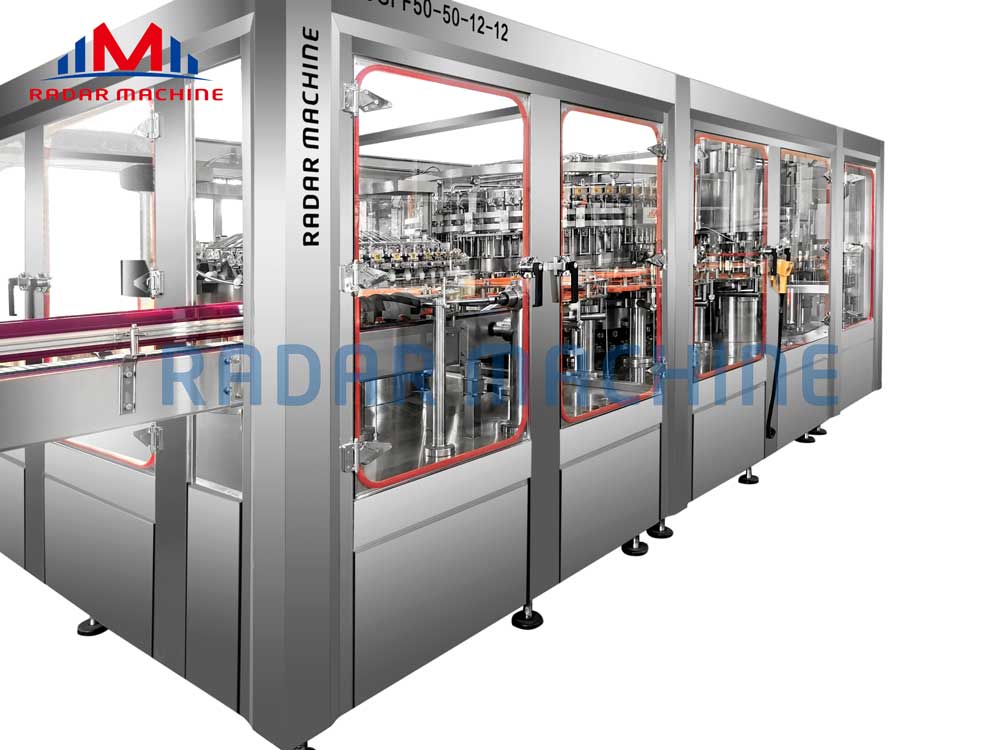

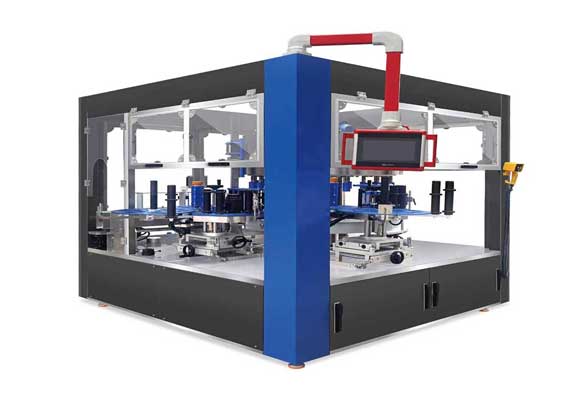

Glass Bottle Beer Filling Machine (3 in 1)

The Beer Filling Machine Wash-filling-capping 3-in-1 unit is designed for producing glass bottled beer. It combines the processes of pressing the bottle, filling, and sealing, reducing material handling and external contact time, while improving sanitation, production capacity, and economic efficiency.

- Combines washing, filling, and capping in a single unit.

- Reduces material handling and external contact time.

- Enhances sanitation, production capacity, and economic efficiency.

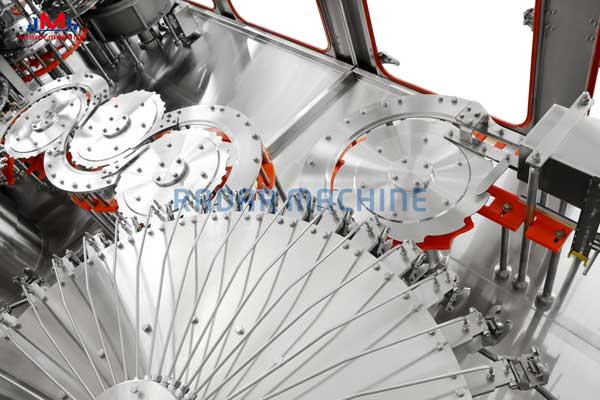

Detailed Images

Video

Machine Parameters

Main features:

Washing Part:

Except the down framework, the transmission parts and some parts that must be made of special materials. Other parts are all made of stainless steel 304.

The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE.

The gripper is made of stainless steel, the position where hold the bottleneck is made of food standard rubber;

Rinsing time can be guaranteed for 4 seconds.

Filling part:

Filling machine with spring-type mechanical lifting equipment to upgrade glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover features.

Long-tube filling valves are adopted, with CO2 fully exchanging with air inside glass bottles, to decrease the rinsing of oxygen effectively. with cylinder liquid level and the back pressure controlled by a variable signal proportional. Fast, stable, accurate, to be vacuum one at a time.

Filler & Capping Machine drive system mainly consists of:

● Filling valve

● Internal isobar filling valve

● Working flowchart

Capping part:

Cap cap-distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

The capper is equipped with inlet bottle detection switch.

Centrifugal way of cap arranging is adopted to reduce damage of caps.

BXGF SERIES TRIBLOC RINSER FILLER CROWNER

● Suitable to filling: beer bottles filling, crown caps

● Container: 150ml to 1000ml glass bottles

● Filling Capacity: 1,000~12,000 bottler per hour

● Filling Style: isobar filling

● Filling Temperature: 0-4°C (cold filling )

● Adopted 2 times deoxygenating system

● Crown Caps Capping System

● PLC control, full-automatic working

● Inverter adjustor, filling speed adjustable

● No bottles no filling, clash bottles auto remove, no bottle no capping

| Model | Washing Heads | Filling Nozzle | Capping Heads | Dimension (mm) | Power (kw) | Capacity (BPH) |

|---|---|---|---|---|---|---|

| BXGF 6-6-1 | 6 | 6 | 1 | 1750*1600*2350 | 1.2 | 500 |

| BXGF 16-12-6 | 16 | 12 | 6 | 2450*1800*2350 | 2 | 3000 |

| BXGF 24-24-6 | 24 | 24 | 6 | 2780*2200*2350 | 3 | 6000 |

| BXGF 32-32-10 | 32 | 32 | 10 | 3600*2650*2350 | 4.7 | 8000 |

| BXGF 40-40-10 | 40 | 40 | 10 | 3800*2950*2350 | 7.5 | 12000 |

| BXGF 50-50-12 | 50 | 50 | 12 | 5900*3300*2350 | 9 | 15000 |

Production Lines Flow Chart

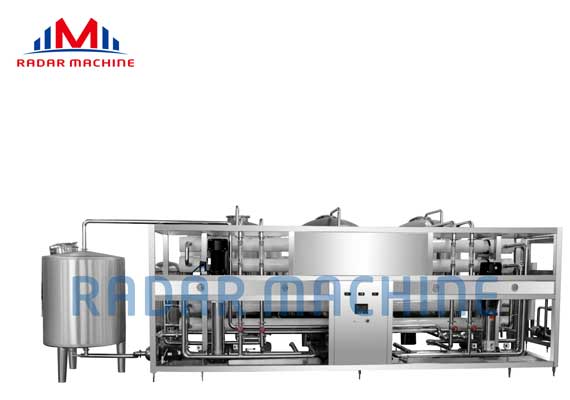

Water treatment system

Water purification machine to treat fresh water for pure, drinking, and mineral water.

Our plant could make drinking water, mineral water, pure water, and potable water from the water sources: Ground, spring, well, river, brackish, lake water etc.

Raw water source: Bore whole, river, well, mountain spring, lake, etc

View Details 》

Blowing Molding System

With our automatic blow molding machine, you can effortlessly create PET plastic containers and bottles in various shapes.

It is widely utilized in the production of carbonated beverage bottles, mineral water containers, pesticide bottles, edible oil containers, cosmetic bottles, wide-mouth containers, and hot-fill bottles.

View Details 》

Automatic Labeling Machine

The thermal shrink sleeve machine has adopted an innovative double-driving structure as its advanced driving mechanism.

With four-wheel driving, it achieves self-centering and equal pressure distribution across all four wheels, facilitating seamless, steady, and rapid label transfer.

View Details 》

Shrink Wrapping Machine

The automatic Linear high-speed film shrink-wrapping machine is suitable for wrapping such products as pop-top, mineral water, and bottles. beer, drinks, etc without a bottom tray, working with a PE film shrink tunnel to pack the goods perfectly, this style machine is suitable for a capacity of over 12,000bph line.

View Details 》

Automatic Double Head Shrink Sleeve Labeling Machine

This machine is built on a durable food-grade stainless steel framework, ensuring minimal vibration and consistent, precise labeling performance.

With advanced cutting and shrinking mechanisms, automated label detection, and user-friendly controls, it delivers high efficiency, accuracy, and convenience, making it a leading solution in its class.

View Details 》

Palletizer Machine

According to a certain order, palletizer stacks the packed products(in box, bag, bucket) to the corresponding empty pallets through a series of mechanical actions so as to facilitate handling and transporting batches of products to improve production efficiency.

Meanwhile it can use stack layer pad to improve the stability of each stack layer. Various forms designed to meet different palletizing requirements.

View Details 》

Carbonated Soft Drinks Mixing System

A beverage CO2 mixer, used in the production of acidification and mixing of various gas-contained beverages(water, syrup, Carbon dioxide), such as citric drink, coke, juice, etc. aerated water, is the main equipment in a drink production line(especially the key equipment in the middle and high grade of drink production).

View Details 》

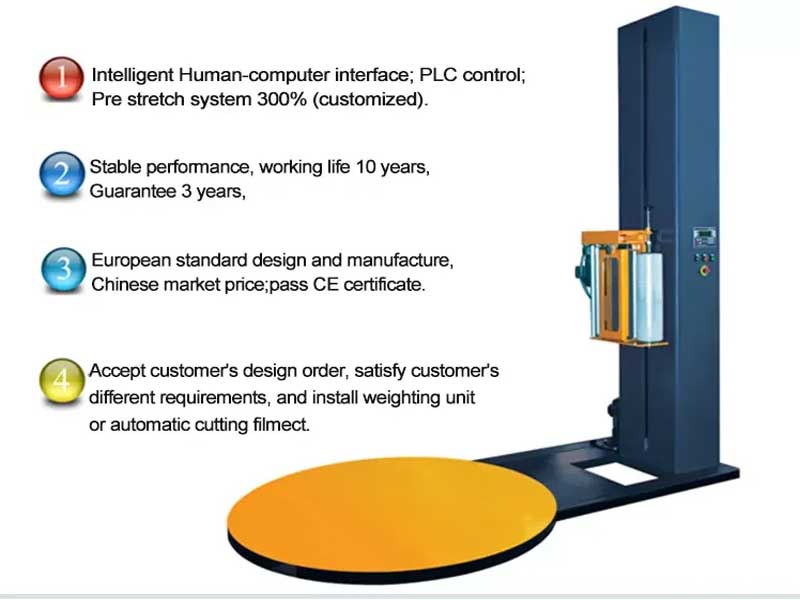

Automatic Pallet Stretch Wrapping Machine

In short, the pre-stretching wrapping machine is to stretch the film in advance in the mold base device when wrapping the film, so as to improve the stretching proportion as much as possible, use the wrapping film to a certain extent, save materials, and save packaging costs for users.

Pre-stretching wrapping machines can save wrapping film to a certain extent

View Details 》

Industrial Inkjet Printer

This inkjet coding machine offers 3-line and barcode printing capabilities, featuring a large color touchscreen for easy setup, long 18-month maintenance intervals, quick cartridge replacement, IP55-rated stainless steel construction, and real-time production efficiency tracking.

View Details 》

Faq

a. What kind beverage you want to produce? Water , juice , carbonated drinks , beer and etc.?

b. contain type, shape and volume? Round, square , 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d. Factory floor plan , voltage and power supply?

e. Your investment and budget?

We are a manufacturer we supply the factory price with good quality, welcome to visit !We can pick you up from at the Zhangjiagang station in our city or in Shanghai airports. Contact our foreign sale team you can get video of our reference running machine.

We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories and check the machines running. You are always welcome to visit our factory in Chine to check the machine running in our factory.

Turnkey projects are available because we can help to start your business in beverage market from PET preform and can making machine, PET bottle blowing machine, water treatment plant , juice or carbonated drink mixing plant , filling and packing machines.

If you have confirmed your size , we help you with the plant layout design accordingly .We can also help with the bottle design, label design and choose the suitable labeling and package type according to your local market. We can help you install the machines, train your staff to operate, maintain the machines and even help you hire experienced Chinese engineers to work in your factory as a production manager .

We have been certificated by the famous certification authority such as ISO and CE .

We offer you high quality machines with 1 year guarantee and provide vulnerable parts free of charge. Every batch of equipments will be debugged before shipment by sending testing video for confirmation. Or you can visit our factory for inspections on site and then ship it after it is qualified. We also supply life-long technical support.

A. If you have clear demand, please inform us, we will make detailed good quote for you soon.

B. If you are new in this filed and don't have clear objectives, you can share us your ideas, investment budget or workshop size, we can make proposal recommendation for you.

When you finish the Preparation conditions(water resource,electricity,air supply,production materials)contact with our sales people we will dispatch engineer to install the machine for you ,and train your employees to use the machine well. Normally when your preparation is done,you can contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 7 days.

We will send one year enough easy broken spare parts together with the machines,shipping together.During the warranty time,we will supply the spare parts with our cost including the delivery fees.

We accept 30% deposit 70%TT before shipment by TT/LC/Western union.

Standard export packing, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety.