Картонная коробка упаковочная машина 10,000 коробок в час

- Для перемещения бутылок используется надувание и сдувание воздуха.

- Сочетает в себе механические, пневматические и электрические системы управления.

- Аккуратно и стабильно загружает бутылки в картонные коробки.

- Эффективно работает с бутылками, движущимися по конвейерной ленте.

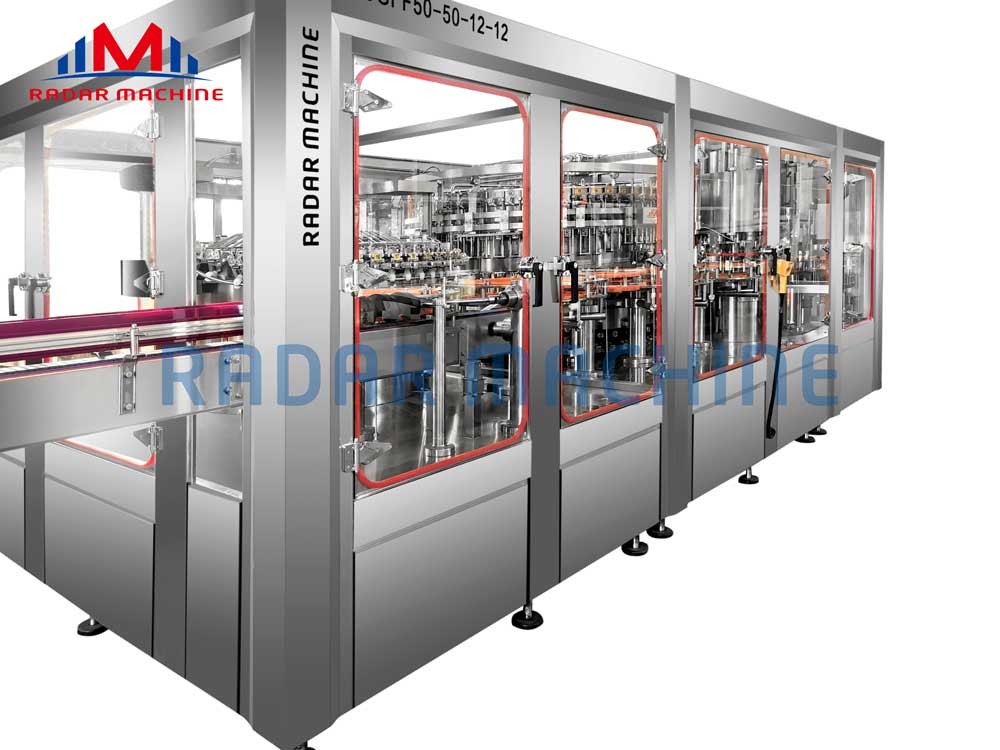

Detailed Images

Video

Machine Parameters

According to customer requirements for product packaging, the product feed for accurate whole column grouping, while underlying pre-sync to the product carton boxes preset position, and then by the lifting mechanism rear jacking good product grouping randomly fall into cartons, lifting mechanism automatically drops to a horizontal position and the outlet conveyor, cartons output by the transport section; each part of the linkage is adjusted by the electric air control to simultaneously ensure that each group of products can be accurate and effective automatic packing and output. Application: Fields of food, beverage, pharmaceutical, cosmetic, chemical, and other. Common to all types of PET bottles, cans, Pak packaging.

Main features :

● Adopt international advanced technology, use imported components and parts, electric components.

● According to carton’s size, automatically adjust the different cartons’ height and width.

● Automatically fold carton up cover, up and down automatically paste adhesive tape, economic and fast and smooth and steady.

● Add the knife protection device,avoid the accident if operate error.

● Operate easy and convenient, can run separately and can also connect with the automatic packaging line.

| Model | SW-300Z | SW-600H | SW-600V |

|---|---|---|---|

| Machine Type | Off or Online Full-AutoType | Online Full Automatic Type | Online Full Automatic Type |

| Wrapping Speed | 0~120Pcs/Hour | 0~60Pallets/Hour | 0~60Pallets/Hour |

| Belt Type | PP Belt, PET Belt, Steel Belt | PP Belt, PET Belt, Steel Belt | PP Belt, PET Belt, Steel Belt |

| Belt Width | 9-16mm (Recommend 12mm) | 9-16mm (Recommend 12mm) | 9-16mm (Recommend 12mm) |

| Belt Thickness | 0.6—0.8mm | 0.6—0.8mm | 0.6—0.8mm |

| Feeding speed of the belt | 2.5-4.5m/s | 2.5-4.5m/s | 2.5-4.5m/s |

| Tension force, infinite regulation | 200 ~ 2500N (As Fact To Match and Choice) | 200 ~ 2500N (As Fact To Match and Choice) | 200 ~ 2500N (As Fact To Match and Choice) |

| Applicable Products | Full Pallets, Pallet Shape Products, Column Shape type etc Products | Full Pallets, Pallet Shape Products, Column Shape type etc Products | Full Pallets, Pallet Shape Products, Column Shape type etc Products |

| Supply Power | About 1.0KW | About 3.5KW | About 6.0KW |

| Voltage, etc | 220V/380V, 3Phase, 50Hz/60Hz (Accept Customize) | 220V/380V, 3Phase, 50Hz/60Hz (Accept Customize) | 220V/380V, 3Phase, 50Hz/60Hz (Accept Customize) |

| Air Pressure | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa |

| Working db | ≤75db | ≤75db | ≤80db |

| Machine Weight | About 300KG | About 900KG | About 1500KG |

| Machine Dimension | W650*D14200*H2300mm (As Fact Machine Model) | W650*D14200*H2300mm (As Fact Machine Model) | W650*D14200*H2300mm (As Fact Machine Model) |

Faq

a. What kind beverage you want to produce? Water , juice , carbonated drinks , beer and etc.?

b. contain type, shape and volume? Round, square , 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d. Factory floor plan , voltage and power supply?

e. Your investment and budget?

We are a manufacturer we supply the factory price with good quality, welcome to visit !We can pick you up from at the Zhangjiagang station in our city or in Shanghai airports. Contact our foreign sale team you can get video of our reference running machine.

We have many projects in different countries, with the customers’ permission, we can guide you to visit the factories and check the machines running. You are always welcome to visit our factory in Chine to check the machine running in our factory.

Turnkey projects are available because we can help to start your business in beverage market from PET preform and can making machine, PET bottle blowing machine, water treatment plant , juice or carbonated drink mixing plant , filling and packing machines.

If you have confirmed your size , we help you with the plant layout design accordingly .We can also help with the bottle design, label design and choose the suitable labeling and package type according to your local market. We can help you install the machines, train your staff to operate, maintain the machines and even help you hire experienced Chinese engineers to work in your factory as a production manager .

We have been certificated by the famous certification authority such as ISO and CE .

We offer you high quality machines with 1 year guarantee and provide vulnerable parts free of charge. Every batch of equipments will be debugged before shipment by sending testing video for confirmation. Or you can visit our factory for inspections on site and then ship it after it is qualified. We also supply life-long technical support.

A. If you have clear demand, please inform us, we will make detailed good quote for you soon.

B. If you are new in this filed and don't have clear objectives, you can share us your ideas, investment budget or workshop size, we can make proposal recommendation for you.

When you finish the Preparation conditions(water resource,electricity,air supply,production materials)contact with our sales people we will dispatch engineer to install the machine for you ,and train your employees to use the machine well. Normally when your preparation is done,you can contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 7 days.

We will send one year enough easy broken spare parts together with the machines,shipping together.During the warranty time,we will supply the spare parts with our cost including the delivery fees.

We accept 30% deposit 70%TT before shipment by TT/LC/Western union.

Standard export packing, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety.